Stainless Steel Processing Technology

The base supporting the pillars of TAKUTEI is made of specially processed stainless steel with a special foundation. Stainless steel is a beautiful metal that is resistant to rust and shines when polished. However, stainless steel is called a difficult-to-machine material, and cutting it is highly difficult. In particular, welding requires skilled techniques.

A laser cutting machine is used to hollow out the shape from a large board. Accurate laser cutting is performed based on input CAD data.

Laser processing is a technology that irradiates high-energy density laser beams onto metals to melt and vaporize them for cutting, drilling, and other processes. Laser processing machines are large machines. Although it is slower than press processing, it can precisely cut through even complex shapes.

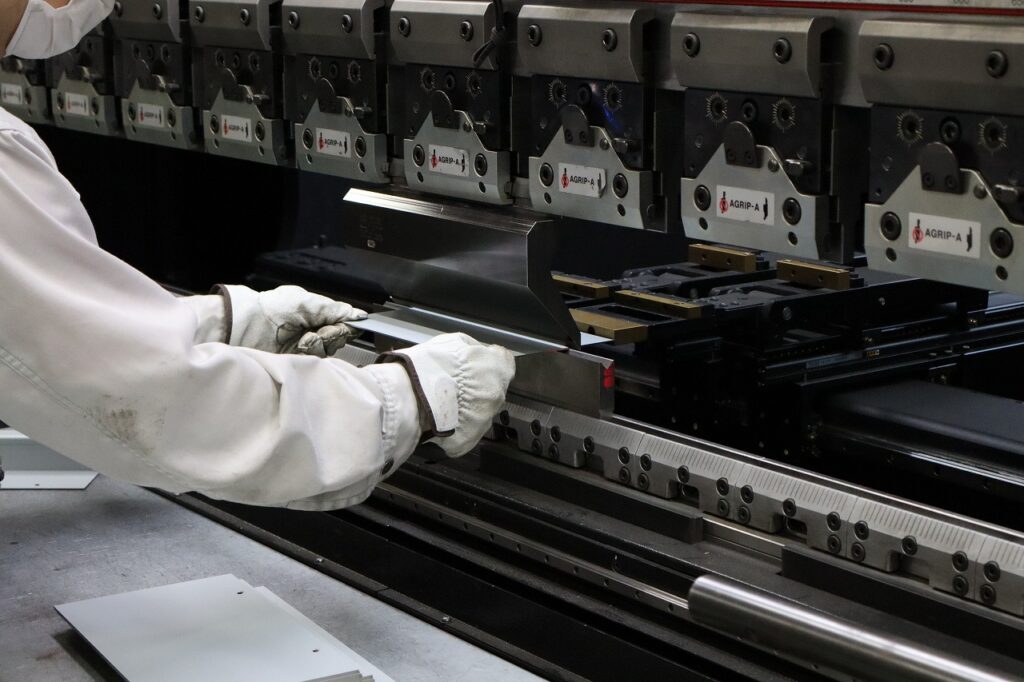

Press machines are used to bend stainless steel. Press machines bend metal by applying pressure from above and below. When powerful pressure is applied to the metal, it exceeds the yield point, the boundary between elasticity and plasticity, and remains permanently deformed. The processing position is aligned manually by expert craftsmen.

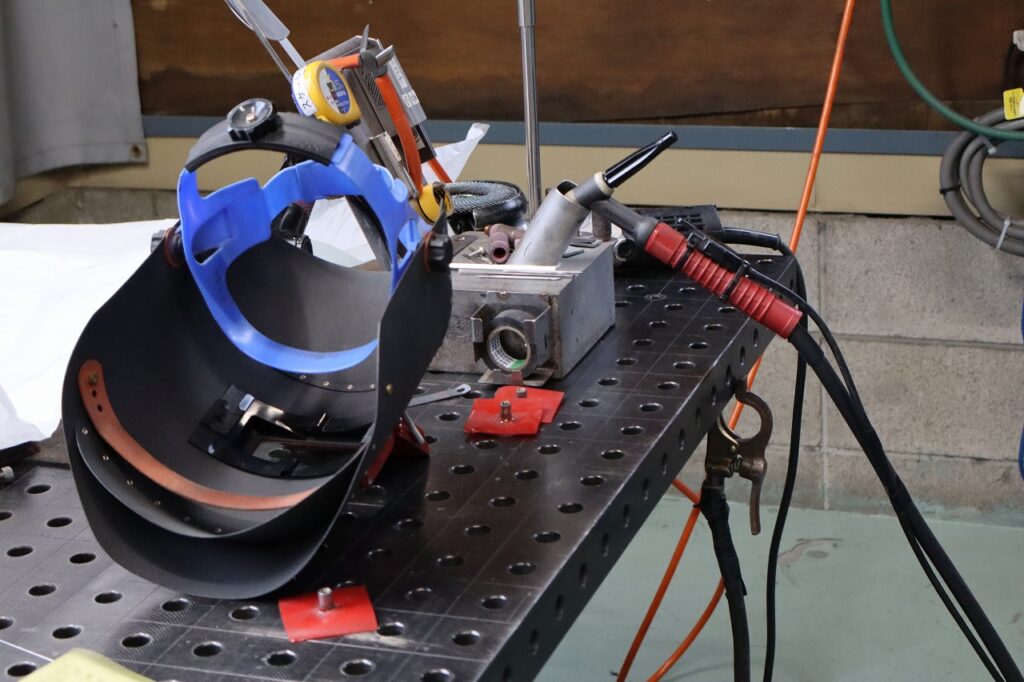

Stainless steel materials are combined by welding. Welding is a method of joining metal materials by applying heat to the joint to make the joint one continuous, integrated component. Arc welding technology is used as the welding method. An arc is an arc-shaped light that is generated by applying a voltage to two electrodes spatially separated from each other. Arc welding is a welding method that uses the heat of this arc to weld metals together.

Welding stainless steel is a very difficult technique. One of the reasons why welding stainless steel is difficult is that stainless steel is very finely classified according to its metal structure and chemical composition. The characteristics of stainless steel vary greatly depending on the steel grade, and the welding method to be selected will also vary. Therefore, it is necessary to be familiar with the characteristics of the base metal and the welding method.